Rapid Prototyping and On-Demand Production for

Robotics & Automation Prototyping

we have years of experience prototyping and manufacturing parts for robotics and automation applications. We use rapid prototyping and digital manufacturing techniques to produce high-performance prototypes and parts that fit seamlessly within complex robotic systems.

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

Why Manufacture

Robotics & Automation Parts with GreatLight?

Get high-quality manufacturing services for your custom robotic and automation prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

ISO certified

GreatLight Rapid Prototyping (GL) is an ISO9001-2015 certified manufacturer that can guarantee top quality parts in an industry that demands rigorous consistency and quality control.

Huge production capacity

We can fulfill orders of virtually any size, from one-off engine part prototypes to full production of injection molded headlamp covers.

Range of services

Equal parts machine shop and digital manufacturing specialist, we offer a range of manufacturing technologies and services, from CNC machining to 3D printing.

Short lead time

Our extensive facilities and partner network allows us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

We have been manufacturing automotive parts for over a decade and our skilled engineers know how to get the best outcomes from your designs.

Easy quotation system

Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

At GreatLigth, we provide robotics and automation customers with rapid prototyping and services like CNC machining and Injection Molding. Our expert team has the knowledge and skills to help bring new product concepts to life. For more information on our prototyping capabilities and how we serve the robotics industry, contact us or request a quote today.

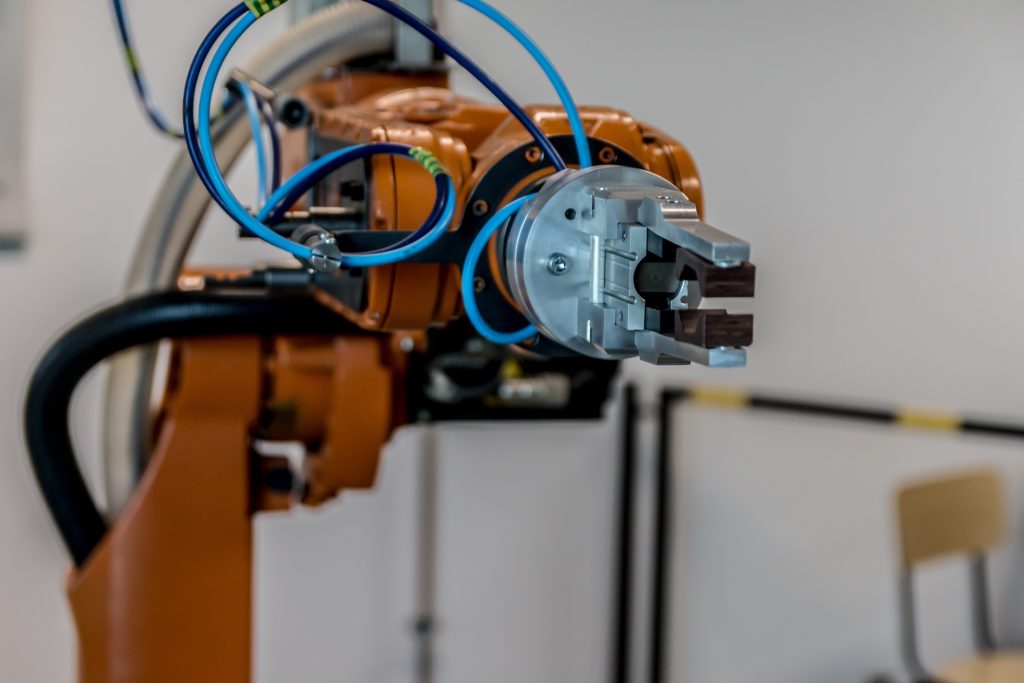

What kind of Robotics & Automation parts

can we make?

The robotics and automation industry requires a wide range of parts made from both metals and plastics.

Typical priorities for robotics customers include:

- Robotic parts

- Prototypes

- Manipulator parts

- Sensors

- Actuators

- Micro systems

- Nano systems

- End effectors

- Motors

- Clamps

- Robotic medical devices

- Casings, housings, tubing

- Conveyor belt components

- Automatic control equipment

- Logic controller components

Robotics & Automation Manufacturing Capabilities

GreatLight offers wide range of manufacturing processes for robotics & automation prototypes and production parts.

Rapid CNC machining

GreatLight operates a large number of CNC machining centers, mills, and lathes (for CNC turning), enabling rapid prototyping of CNC machined parts made from plastic or metal. We offer a wide range of material and finishing options and the potential to combine CNC machining with other rapid prototyping processes.

Rapid 3D printing

Rapid tooling

Rapid tooling (bridge tooling or prototype tooling) refers to the rapid CNC machining of metal tooling for injection molding. It is therefore the first step toward rapid injection molding.

Rapid sheet metal prototyping

Rapid sheet metal prototyping is a set of rapid prototyping services for the production of sheet metal parts. This includes various forming, cutting, and assembly processes for manipulating the sheet metal stock in different ways.

Robotics & Automation Prototyping FAQs

Yes, GreatLight Rapid Prototyping is an ISO9001-2015 certified manufacturer. We manufacture parts to a high standard, no matter the project or the customer.

For certain manufacturing processes like injection molding, we can provide a T1 sample for your parts, then further samples if required.

We can fulfill orders quickly, but lead times depend on a few factors, such as the manufacturing process, order quantity, and part complexity. CNC machined parts can take as little as five days, 3D printed parts can take as little as three days, while moldings made via rapid tooling can take as little as 5–7 days.

GreatLight values privacy and security with the utmost seriousness and will happily sign a non-disclosure agreement (NDA) at your request, giving you peace of mind about your intellectual property.