What parts are generally processed by CNC machining?

About CNC machined parts

CNC machining plays a very high role in CNC equipment. Many parts processing companies will use CNC machining centers. So what types of parts can CNC machining process?

As we all know, CNC machining centers are suitable for processing parts that are complex, have many processes, have high requirements, require multiple types of ordinary machine tools and numerous tool fixtures, and require multiple clamping and adjustments to complete the processing.

Box parts

Generally refers to parts with more than one hole system, a cavity inside, and a certain proportion in the length, width, and height directions. Such parts are commonly used in machine tools, automobiles, aircraft manufacturing and other industries. Box-type parts generally require multi-station hole system and surface processing, and the tolerance requirements are relatively high, especially the geometric tolerance requirements are relatively strict. They usually need to go through milling, drilling, expanding, boring, reaming, countersinking, tapping and other processes. , requiring more tools.

Special-shaped parts

Special-shaped parts are parts with irregular shapes, and most of them require mixed processing of points, lines, and surfaces at multiple stations. The rigidity of special-shaped parts is generally poor, the clamping deformation is difficult to control, and the processing accuracy is difficult to guarantee. Even some processing parts of some parts are difficult to complete with ordinary machine tools. When processing with a machining center, reasonable technological measures should be adopted, one or two clampings, and the characteristics of the multi-station point, line, and surface mixed processing of the machining center should be used to complete multiple processes or all process contents.

Discs, sleeves and plate parts

Disc sleeves or shaft parts with keyways, radial holes, or hole systems distributed on the end face, curved surfaces, such as shaft sleeves with flanges, shaft parts with keyways or square heads, etc., as well as those with more holes Processed plate parts, such as various motor covers, etc. Disc parts with distributed hole systems and curved surfaces on the end surface should choose a vertical machining center, while those with radial holes can choose a horizontal machining center.

complex surface

After mastering the functions of the machining center, with certain tooling and special tools, the machining center can be used to complete some special process work, such as engraving, engraving lines, and patterns on metal surfaces.

Special processing

With certain tooling and special tools, the machining center can be used to complete some special process work, such as engraving, engraving lines, and patterns on metal surfaces.

From the above introduction, it is not difficult to see that CNC machining centers have a wide range of applications and process many types of workpieces. Therefore, many companies need to use CNC machining centers for processing precision parts, molds, etc.

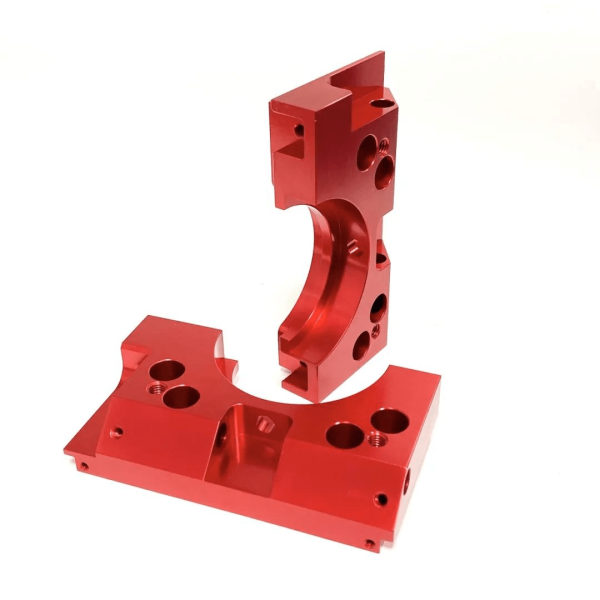

The following are some of the CNC processed parts of “GreatLight”